Don’t underestimate the impact of accurate energy modelling on the thermal performance of building envelopes. Padraic O’Connell explains.

On our path to a more sustainable future, building envelope design is playing an increasingly important role in the energy efficiency of buildings. As a result, the way we assess envelope thermal performance is growing in significance and complexity.

The Challenge: Modelling Real-Life

Until recently, envelope thermal performance had been modelled “incorrectly”. A big call, but what we mean is, energy modelling used an effective R-value for opaque envelope assemblies and uniformly applied it to the entire planar assembly.

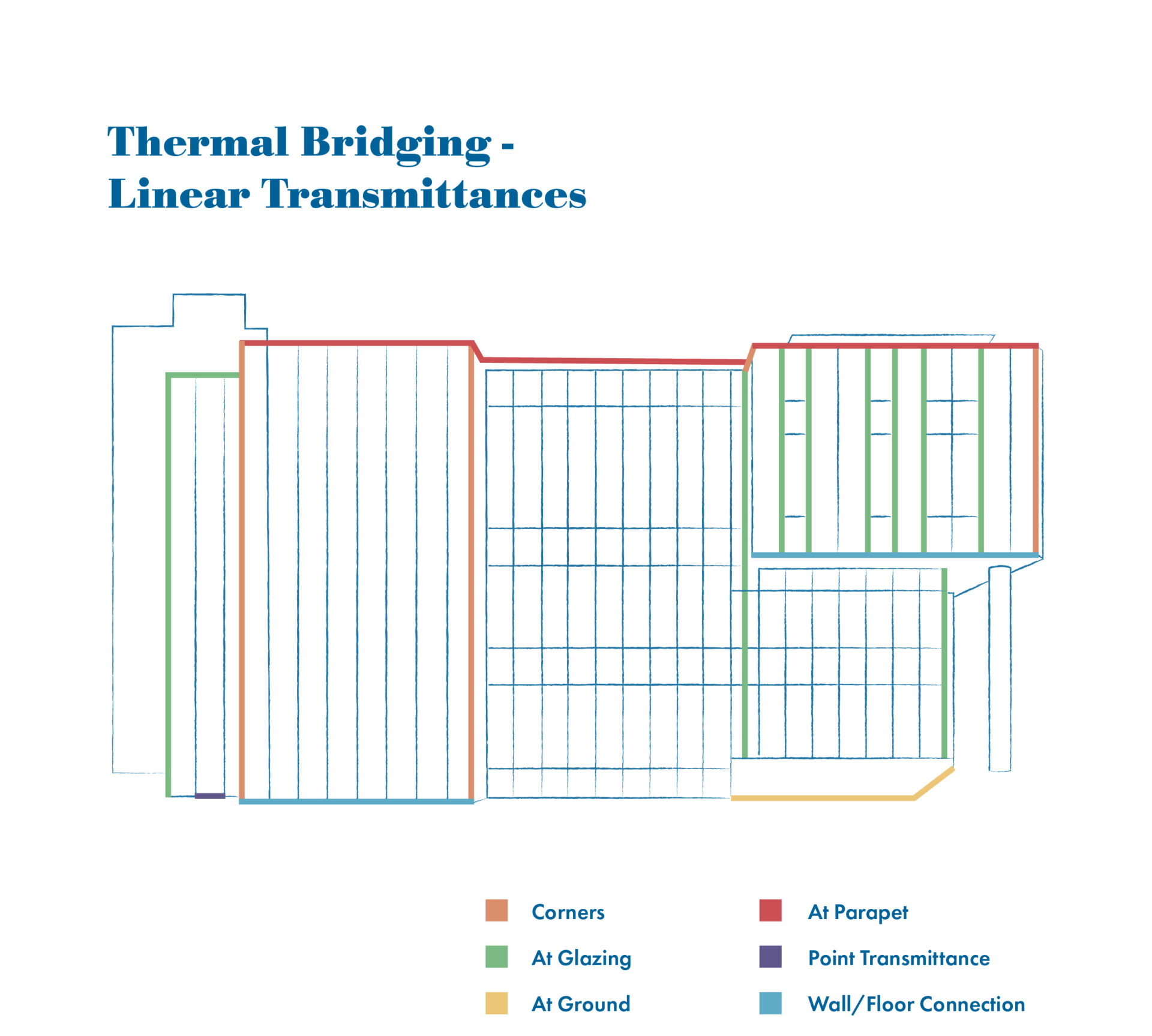

The effective R-value of an envelope assembly is the nominal R-value, including the 2D thermal bridging effect of repetitive framing (e.g., stud framing). However, this isn’t an accurate representation of real-life thermal bridging as it doesn’t address non-repeating linear transitions (such as window rough openings, balconies, parapets, and corners) and point penetrations (such as structural beams through the envelope or mechanical equipment). Significant heat loss can occur in these areas, impacting energy performance.

Linear transmittance modelling example for the Mathison Hall Expansion, University of Calgary, Alberta.

Accurately Predicting Performance

Using realistic R-values for assemblies is key not only to accurately predicting energy performance, but also for HVAC load calculations and equipment sizing. And for projects with strict targets, such as public-private partnerships, net zero, and owner-operated, it’s even more important to use accurate envelope values in the energy analysis. These projects require exact energy model inputs to give confidence that the unyielding energy, cost, and carbon targets can be realized.

The impact of linear and point transmittance can reduce the effective R-value from 25% to 50%, depending on the envelope type (e.g., wood frame, steel frame, concrete or masonry, etc.). So an effective wood frame wall with an R-value of R25 can be R19 overall effective. The impact of linear transmittance on steel will be larger than wood, so an effective steel frame wall with an R-value of R17 can be R8 overall effective. Envelope detailing is vital to minimizing heat loss at linear and point transitions. When it comes to adding more insulation to reach a desired R-value, the law of diminishing returns eventually takes effect – focusing on continuity of insulation and the specific factors that are causing the thermal bridges is a more appropriate approach.

Are Your Targets Accurate?

For your next project, ask your Footprint energy modelling consultant to help guide building envelope decisions as an important step in safeguarding energy and carbon targets as well as meeting the owner’s bottom line. The result will be fewer surprises and a higher performing building.

Padraic O’Connell has more than a decade of experience. Well regarded in the industry, he has built up a diverse range of projects, specializing in sustainable design and energy-efficiency.